EPSAN Unveils Advanced Laser Marking Capabilities for Polyamides

EPSAN, a leader in polyamide compounder, is excited to announce a new development in laser marking capabilities for polyamides. This innovative solution allows for a more efficient, precise, and sustainable solution for marking and identifying polymer products.

What is Laser Marking?

Laser marking is a process that uses a focused beam of light to create permanent marks on the surface of a material. This method is highly precise and can produce detailed designs, text, and codes without physically contacting the application.

Key Features and Benefits of Laser Marking

-

Enhanced Precision and Efficiency: Our newly developed laser marking technology ensures precision in marking polyamides, allowing for high-definition, permanent marks without compromising the material's integrity. This advancement significantly enhances the readability and durability of markings, crucial for applications requiring long-term traceability and identification.

-

Versatile Color Marking: A key feature of this new technology is its ability to mark polymers in a variety of colors. This capability allows for greater flexibility and customization in product design and identification.

-

Sustainable and Environmentally Friendly: In line with our commitment to sustainability, the new laser marking technology eliminates the need for harmful inks and chemicals traditionally used in polymer marking processes.

Applications and Uses of Laser Marking

Laser marking technology is versatile and can be applied across various industries, including:

-

Automotive: Marking parts with serial numbers, logos, and other identification marks.

-

Electronics: Labeling components with barcodes, QR codes, and technical information.

-

Consumer Goods: Customizing products with brand logos, decorative designs, and personalization options.

Whether for serial numbers, barcodes, logos, or other essential markings, our technology ensures that each mark is precise, clear, and long-lasting.

Epsan’s Laser Marking Test Capability

-

Diode lasers with wavelengths in the range of approximately 800 nm to 1000 nm are now, in addition to Nd:YAG lasers (1064 nm), the most important industrial lasers for processing of plastics.

-

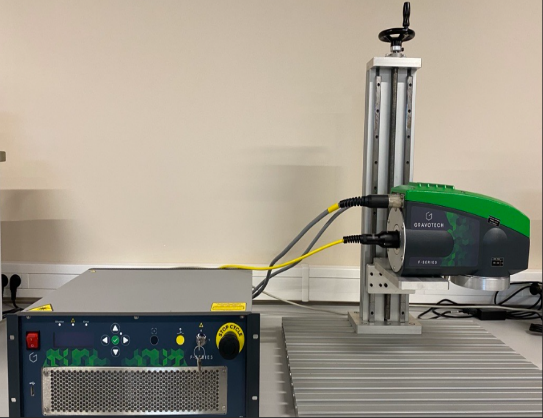

Diode laser marker equipped to meet the needs of Industry 4.0, the fiber laser engraver performs precise markings in very short cycle times.

-

Diode laser marking equipment can operate at energy levels of 20W, 30W and 50W. 20W is adapted for most of the applications for a surface marking, 30W is the solution for your fast and high-contrast markings, and 50W is the most suitable solution for deep laser markings.

-

Fiber laser frequency is between 2-200 Khz. Scan speed is up to 10000 mm/s

-

Laser markability does not affect flammability properties.

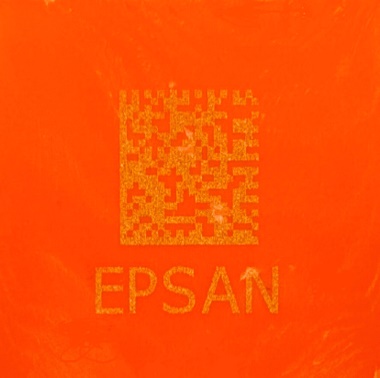

Epsan developed a new grade EPLAMID 6 GX0 30 ORNG Q1D0C201™ RAL 2003 color.

In the rapidly evolving e-mobility sector, safety and traceability are paramount, especially in high-voltage applications. The distinct orange color of the material in these applications serves as a crucial safety feature, signaling the presence of high voltage and ensuring that the components are easily identifiable during manufacturing, assembly, and maintenance processes.

Furthermore, incorporating laser marking capabilities into these connectors enhances traceability and compliance with industry standards. Laser marking provides precise, durable, and permanent markings that withstand harsh environmental conditions, ensuring that critical information such as serial numbers, batch codes, and safety symbols remain legible throughout the product’s lifecycle.